Reduce fleet costs

Significantly reduce your fuel consumption, vehicle insurance and repair costs.

How can we help?

Reduce fleet costs

Significantly reduce your fuel consumption, vehicle insurance and repair costs.

Optimise On-time delivery and productivity

Helping you optimise productivity significantly.

Improve driver and vehicle safety

Get instant visibility of driving behaviours and improve driving performance.

Fleet management solutions

Partners

Insights

We are MICHELIN

What's new?

Events

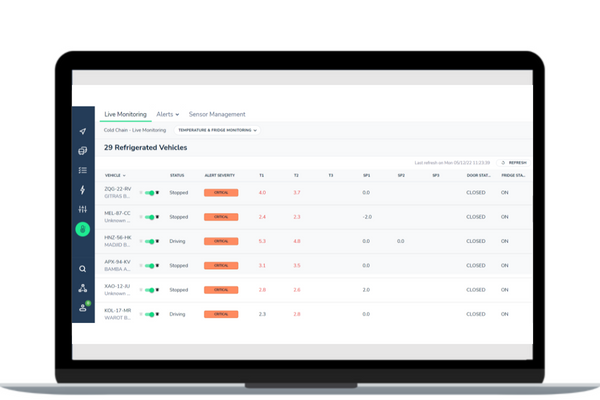

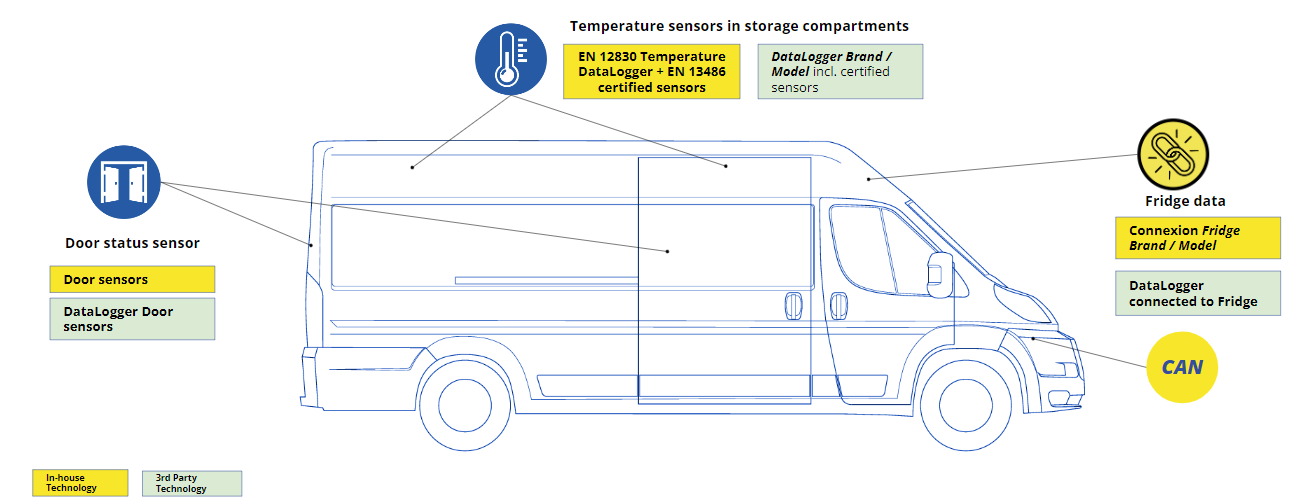

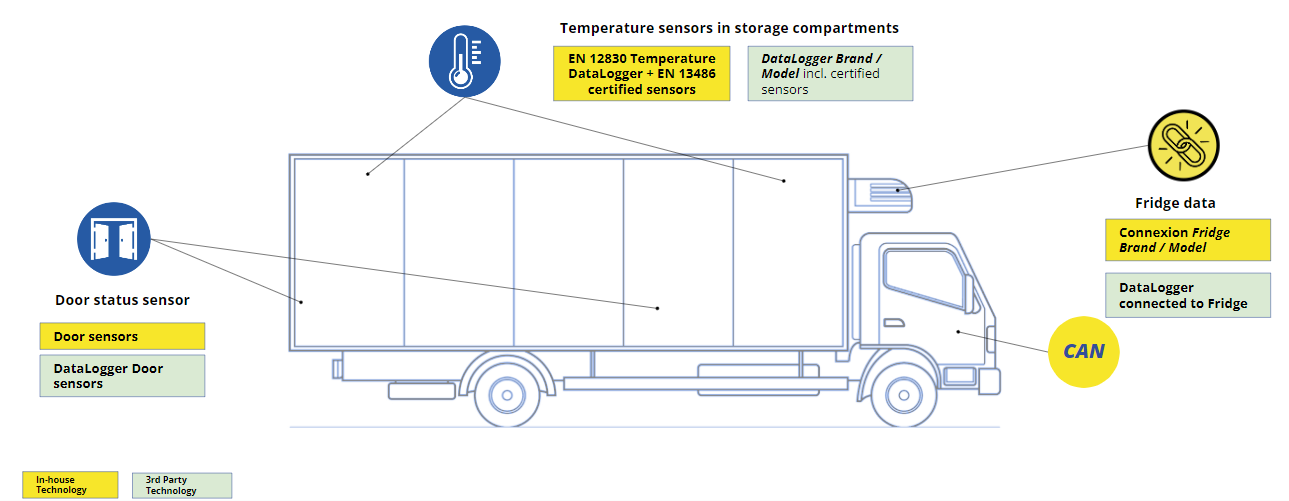

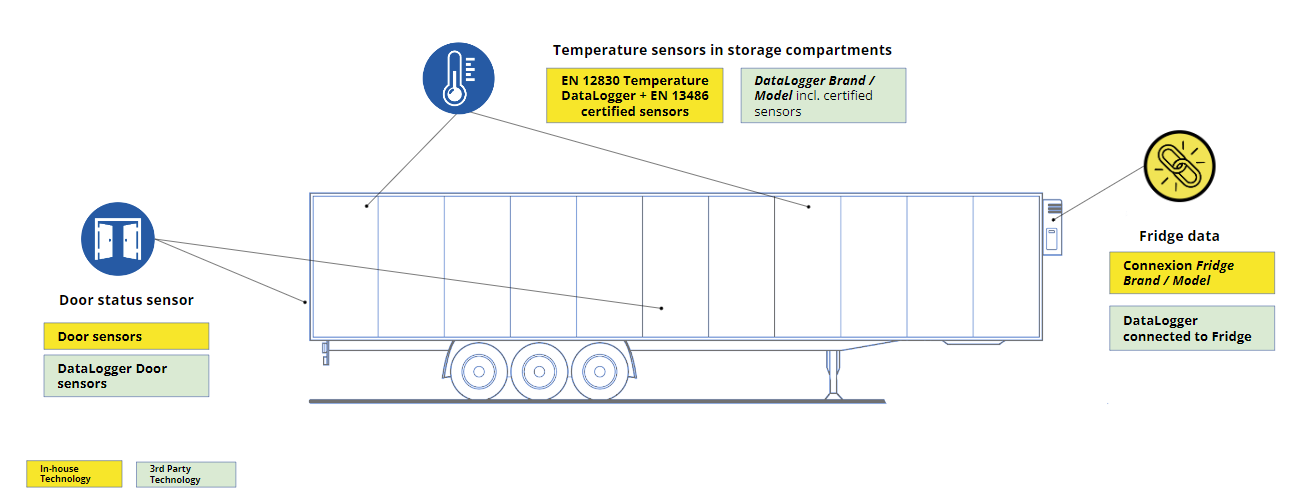

Connected Temperature is our cold chain tracking and cargo temperature monitoring solution. Maintain the integrity of your delivered goods, by always being made aware of the temperature of your cargo and reporting on and proving your cold chain integrity to your final customer or any third parties.

%20(7).png)

![]()

Establishing temperature zones and thresholds based upon requirements of goods transported

![]()

Setting up bespoke incident duration alerts defined by cargo temperature needs

![]()

Disabling the alerts once the cargo has been delivered

![]()

Incident alerts with real time temperature excursion alerts for any breaches of the previously designed temperature threshold

.png)

![]()

Automatic reports to send to your final customer for both individual trips and overall operations

![]()

Quick reports downloads for third parties such as authorities or audits

![]()

Historical reports to build an in-depth understanding of what is happening with your cold chain fleet

![]()

Alerts when the fridge is turned on or turned off

![]()

Maintenance issues alerts related to the correct functioning of your fridge

![]()

Integrating the temperature settings of your fridge and your cold chain monitoring solution

+

A cold chain is a specialised type of supply chain or logistics system that is designed to control and maintain the temperature for a wide range of perishable goods that are sensitive to fluctuations in temperature.

+

Examples of common products contained within a cold chain include foodstuffs such as fresh produce (fruit and vegetables), dairy products (milk and cheese), meat and poultry (beef, chicken etc.), seafood (fish and shellfish), and an array of frozen foods. A cold chain may also comprise pharmaceutical goods like vaccines and medications.

+

The cold chain is important because certain products will either perish or lose their efficacy without proper temperature control. For instance, the majority of foods will become unsafe for consumption if they are not stored at certain temperatures, and most vaccines and medicines will become ineffective owing to their chemical sensitivity.

+

A cold chain works by having a series of set tasks carried out until a product is moved from its point of origin to its final destination. The key steps of a cold chain involve the preparation of the product, its placement in a temperature-controlled storage unit, transportation under controlled conditions, and finally, delivery to the intended recipient.

+

Cold chain tracking refers to the continuous monitoring of temperature-sensitive cargo as it moves through the supply chain. It guarantees that items such as food, drink, and medicines remain within the required temperature range during transport.

+

Cold chain management means safeguarding the quality and safety of goods which must be kept within strict temperature ranges. If temperature deviates, fleet managers need immediate visibility so they can respond and prevent potential damage.

+

Cold chain monitoring ensures that goods arrive in perfect condition by maintaining the correct temperature throughout transport. When temperatures fluctuate, products can spoil, be rejected by customers, or even create health risks. By using cold chain telematics, managers gain real-time insight which reduces financial losses, supports regulatory compliance, and protects a business’s reputation.

+

A break in the cold chain happens when the prescribed temperature-controlled environment for a perishable product is compromised. Such breaks can occur due to equipment malfunctions, temperature zone fluctuations, delays, human errors, power outages, or packaging issues.

Importantly, a break in the cold chain indicates that a product has not been handled in accordance with its prescribed temperature requirements or with the regulations that are in force.

It is crucial that fleet managers working within a cold chain guarantee that compliance with regulations is ensured throughout the entire transportation process for two primary reasons. That is, breaches in cold chain regulations pose both risks to public health and the economy.

The former concerns physical safety in preventing consequences like food poisoning, with the latter regarding the implied financial impact. Specifically, a customer is within their rights to refuse a delivery if they feel that a cold chain has been broken in transport, and moreover, regulations breaches constitute grounds for damage compensation.

We at MICHELIN Connected Fleet understand the importance of maintaining cold chain compliance, and so have developed cold chain tracking and monitoring solutions that make it easy to uphold the quality of goods your fleet transports.

Our solutions give fleet managers comprehensive visibility, the ability to adapt to different temperature zones, and proof of compliance for your customers’ peace of mind.

Schedule a demo and find out how MICHELIN Connected Fleet can help your business or speak to an expert who will answer any questions you have.

.jpeg?width=301&height=341&name=Untitled%20design%20(95).jpeg)

Sales: +44 113 281 4899

Customer Support: +44 113 281 4842

Lynton House

7-12 Tavistock Square

London

WC1H 9LT

Privacy Policy | Cookie Notice | Legal Notice | Legal Information

©2026